Sand-blasting Machine

Product information

1、Definition and function of the sand blasting machine

Sand-blasting machine is a kind of surface treatment equipment that can clean, remove rust, remove oxidation layer, increase roughness or achieve decorative effect by spraying abrasive (such as quartz sand, steel balls, glass beads, etc.) on the surface of the workpiece. Its core functions include:

Surface cleaning: remove oil, rust, old coating, etc.

Surface coarsening: to enhance the adhesion of the coating (such as spraying, pretreatment before electroplating).

Decorative processing: to achieve matte, wire drawing and other special texture effects.

Deburring: Clean the burrs and flash edges of castings and machined parts.

2、 Classification and working principle of the sand blasting machine

1. Categorize by motivation

Pressure sandblasting machine:

Principle: Compressed air is used to spray abrasive from a closed pressure tank at high speed.

Features: Strong impact, suitable for large workpieces or high hardness materials (such as steel, stone).

Suction (siphon) sandblasting machine:

Principle: The abrasive is sucked in and mixed by the air siphon effect.

Features: Simple structure, suitable for small workpieces or fine processing (such as glass, plastic).

Wet sandblasting machine:

Principle: abrasive is mixed with water and sprayed to reduce dust pollution.

Features: Environmentally friendly, suitable for dust-sensitive environments (such as indoor, precision parts).

2. Type by application scenario

Portable sandblasting machine: Small equipment, flexible for field maintenance or small batch operations.

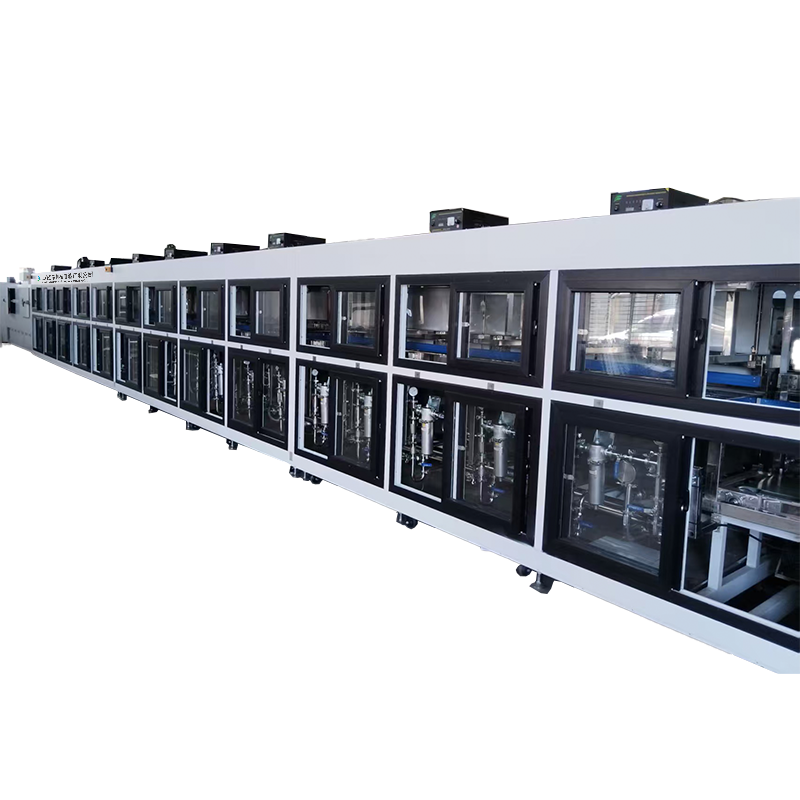

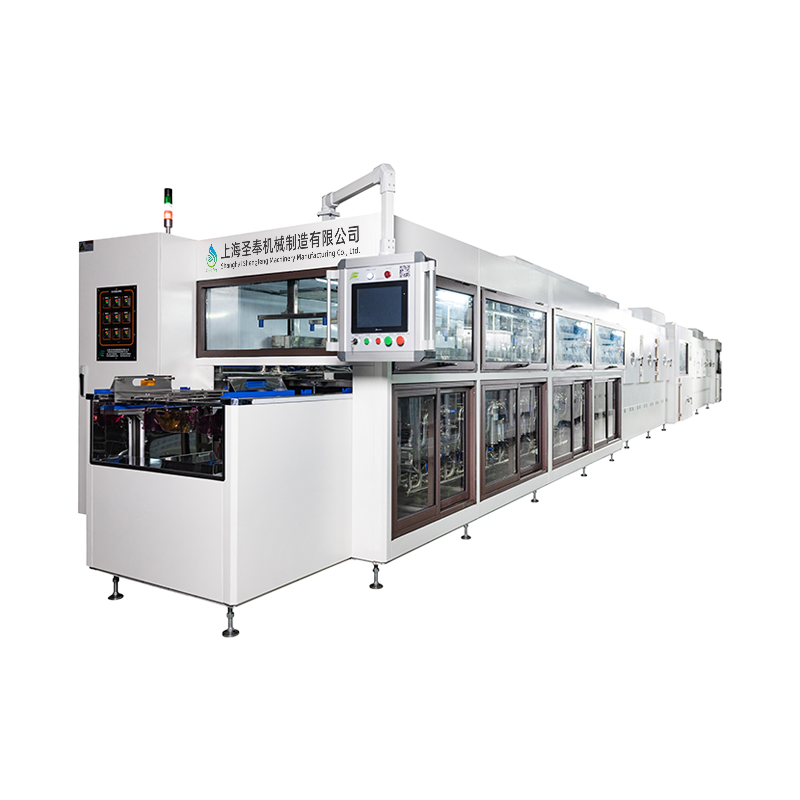

Automatic sandblasting machine: integrated conveyor belt or mechanical arm for line production.

Sandblasting room: large-scale sandblasting operation in confined space, equipped with dust removal system.

3. Core components and technical parameters

Core components:

Spray gun: Control abrasive spray direction and pressure.

Abrasive tank: storage and circulation of abrasive (e.g., steel sand, brown corundum, ceramic beads).

Compressed air system: provides injection power (pressure range 0.5-0.8MPa).

Dust removal system: Filter dust, protect the environment and the operator (such as cartridge dust remover).

Technical parameters:

Parameter Typical values/Description

Sand blasting pressure 0.4-0.8MPa

Abrasive consumption 10-50 kg/h (depending on workpiece material and area)

Treatment efficiency 1-10 m²/h (such as steel plate rust)

Power 3-15 kW (depending on equipment size)

Applicable abrasive particle size 0.1-3mm (quartz sand, glass beads, stainless steel balls, etc.)

4. Application field

Metal working:

Auto parts rust removal, ship steel plate pretreatment, steel structure coating pretreatment.

Aerospace:

Engine blade cleaning, composite surface coarsening.

Electronics & Precision Manufacturing:

Semiconductor package deburring, optical device matte processing.

Architecture and Heritage Restoration:

Antique treatment of stone surface, clean concrete.

Product advantages

1、advanced equipment technology, exquisite workmanship

2、Long normal service life, high pass rate, to the technical level of imported equipment, more cost-effective.

3、our company has nearly 20 years of experience in technical and after-sales service team, from design and production to after-sales service to provide customers with professional solutions.

5.Selection suggestions

Precision parts (such as electronic components) : suction or wet sandblasters.

Select according to production needs:

Small batch/multi-variety: manual portable equipment.

Environmental requirements:

Preferred choice is a wet sandblasting machine or equipped with an efficient dust removal system (such as a cartridge dust collector).

6.Maintenance and safe operation

Daily maintenance:

Clean the abrasive tank and gun regularly to prevent clogging.

Check tightness of air pipes and joints to avoid air leakage.

Abrasive Management:

Sift and recover abrasives to remove dust and impurities.

Replace abrasives according to the material of the workpiece (such as stainless steel parts with no iron abrasives).

Safety specifications:

Operators should wear protective clothing, goggles and dust masks.

Ensure ventilation and explosion-proof measures when working in confined Spaces.

7. Environmental protection and innovation trends

Green blasting technology:

Biodegradable abrasives (e.g. Walnut shell, corncob) replace traditional sand.

Dry ice sandblasting without water, zero waste discharge.

Intelligent upgrade:

Integrated AI visual recognition, automatic adjustment of sandblasting parameters.

The Internet of Things (IoT) remotely monitors device status and maintenance alerts.

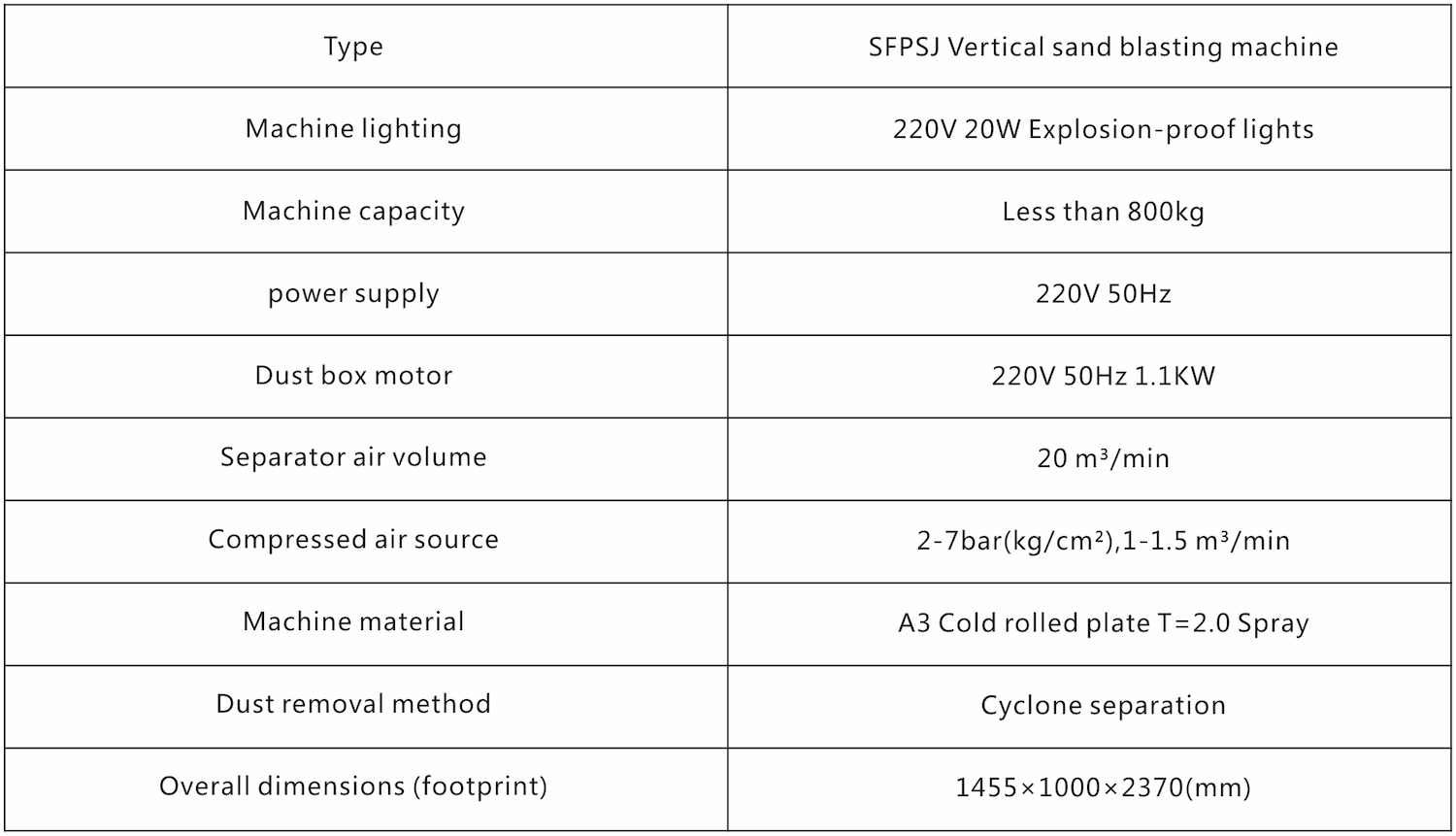

Technical indicators

For more models of products, please contact us. We will be happy to serve you!

在线留言