Independent Four-chamber Curing Oven

Product information

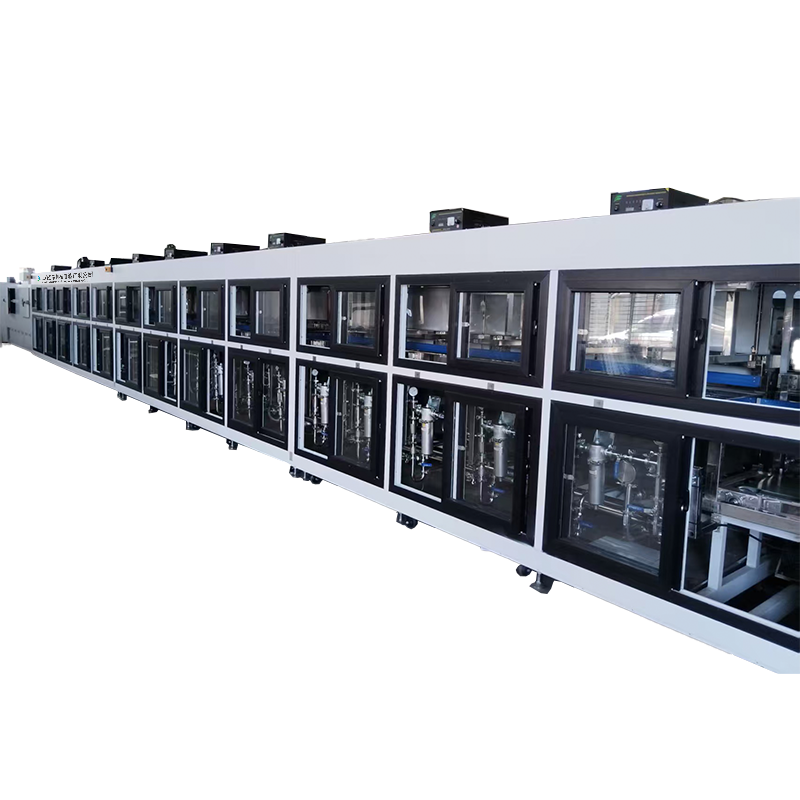

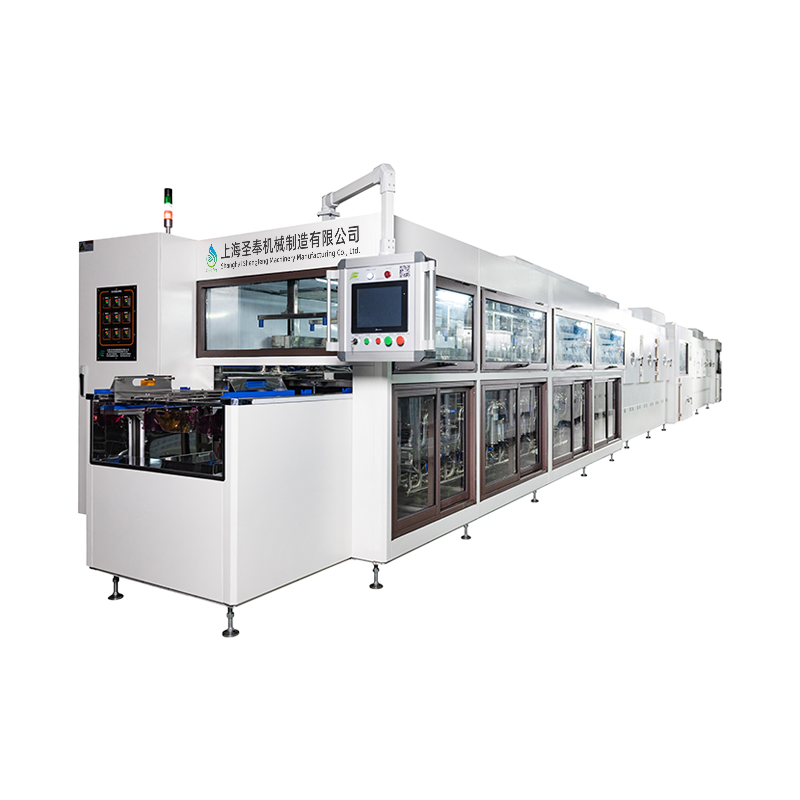

The basic principle of an independent four-cavity curing oven is to use electricity as a thermal energy source to generate heat from electric heating elements,convective heat transfer using a fan,heat transfer of materials,and continuous replenishment of fresh air and discharge of humid air.Its greatest feature is that the hot air in each chamber is circulated in its respective box,which improves the thermal efficiency and saves energy.

1、Definition and function

Independent four-cavity curing oven is an industrial or laboratory heat treatment equipment equipped with four independently controlled temperature working chambers, which can simultaneously handle samples or products at different temperatures and different process requirements. Each chamber operates independently, without interference, and is suitable for scenarios requiring batch and multi-task processing, such as material drying, curing, aging testing, etc.

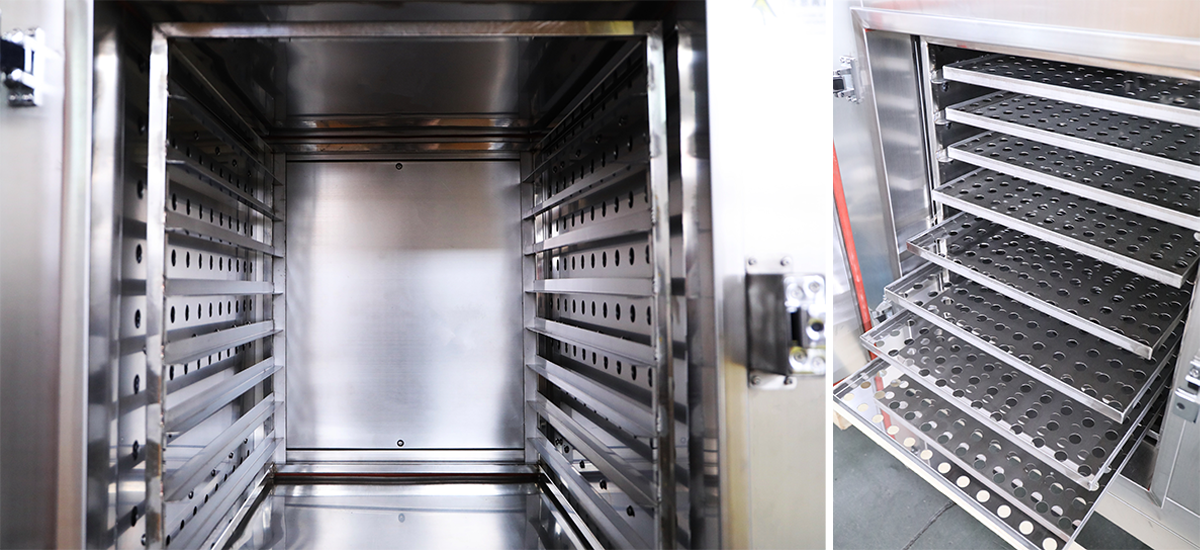

2、Structure and design characteristics

Independent chamber design:Four independent chambers: Each chamber is equipped with an independent heating system, temperature control module and ventilation device, which can separately set temperature, time and other parameters.

Isolation door structure: The insulation sealing door is used between the chambers to avoid the cross-influence of heat.

Heating system:Electric heating: commonly used stainless steel heating tube or quartz heating tube, heating uniform and fast response speed.

Forced convection: Built-in circulating fan to ensure indoor temperature uniformity (temperature difference ≤±1℃).

Control system:Multi-channel temperature control: each chamber independent PID control, support programmatic heating, insulation, cooling.

Touch screen operation: Man-machine interface (HMI) centralized management, real-time monitoring of each chamber status.

Security protection:Over temperature protection, over voltage protection, power failure memory function.

Chamber door open automatic power off, prevent high temperature scald.

3、Technical parameters

Parameter Typical values/Description

Single chamber effective volume 50L-500L (optional according to model)

Temperature range Room temperature +10℃ -300 ℃ (up to 500℃ for high temperature type)

Temperature control accuracy ±0.5℃ -± 1℃

Heating rate 3℃ -5 ℃/ min

Power supply 380V/50Hz (three-phase) or 220V/ single-phase

Material outer box: cold rolled steel spray; Inner chamber: SUS304 stainless steel

4. Application field

Electronics Industry:

PCB board curing, semiconductor packaging glue drying, electronic components aging test.

Chemical Materials:

Resin curing, coating drying, powder material drying.

Medicine and Food:

Pharmaceutical drying, sterilization of medical devices, food dehydration (subject to GMP/HACCP standards).

Research Laboratory:

Heat treatment experiment of materials, simultaneous testing of multiple control samples.

Product advantages

1、advanced equipment technology, exquisite workmanship

2、Long normal service life, high pass rate, to the technical level of imported equipment, more cost-effective.

3、our company has nearly 20 years of experience in technical and after-sales service team, from design and production to after-sales service to provide customers with professional solutions.

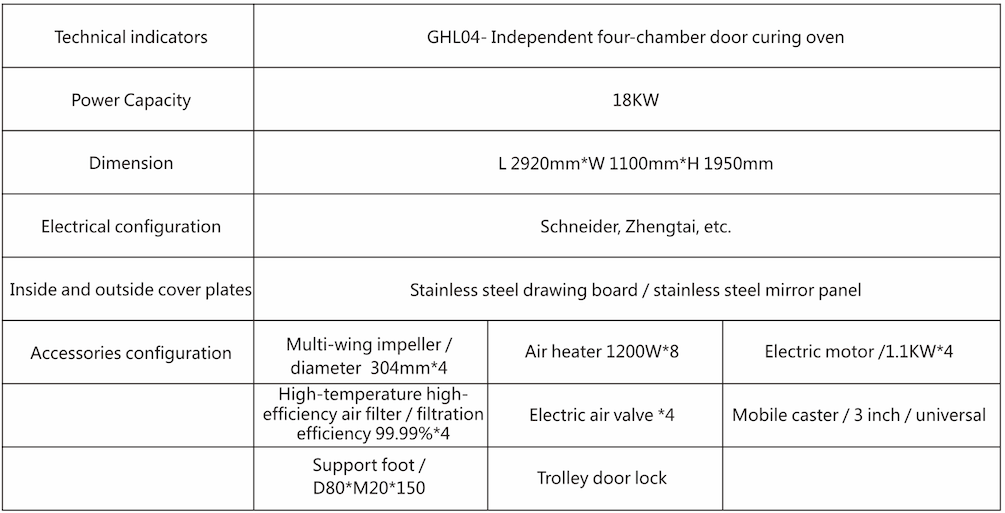

Technical indicators

For more models of products, please contact us. We will be happy to serve you!

在线留言