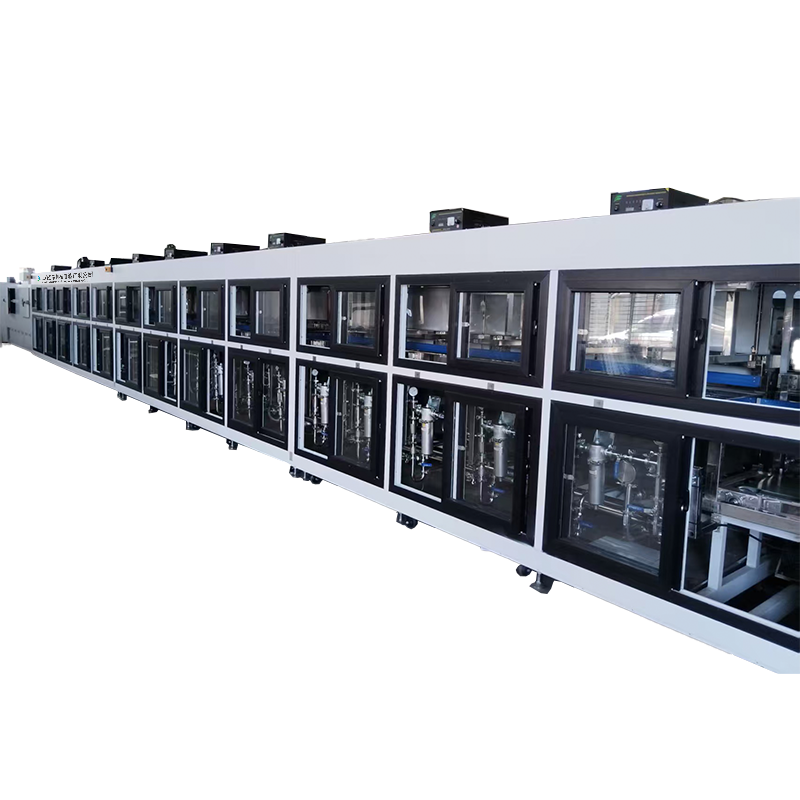

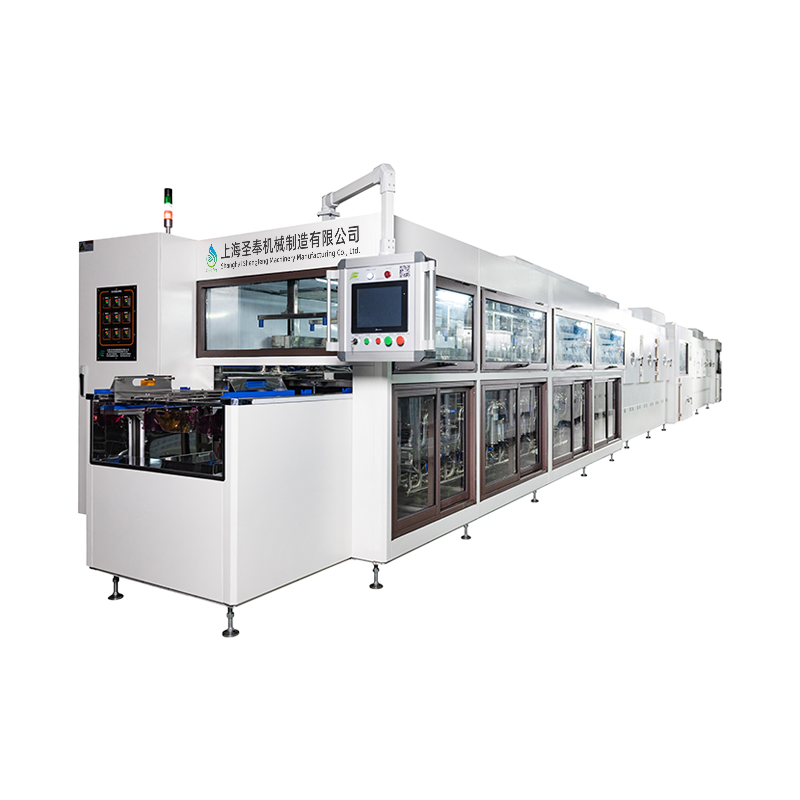

Alcohol Cleaning Machine

I. Definition and Core Functions

An alcohol cleaning machine is a device that uses alcohol (e.g., isopropyl alcohol, IPA) or other solvents as cleaning media, primarily designed to remove oil stains, dust, fingerprints, and chemical residues from the surfaces of precision workpieces. Its core functions include:

1. High-Efficiency Degreasing: Utilizes ultrasonic, spray, or vapor-phase cleaning technologies to penetrate workpiece crevices, achieving thorough cleaning without dead zones.

2. Drying Treatment: Some models integrate drying systems to eliminate watermarks or solvent residues, improving yield rates for subsequent processes (e.g., electroplating, coating).

3. Environmental and Safety Compliance: Equipped with solvent recovery, explosion-proof systems, and automatic fire suppression devices to reduce volatilization risks and environmental pollution.

II. Technical Features

1. Ultrasonic Cleaning Technology:

- Dual-Frequency Ultrasonics (e.g., 40kHz/80kHz): Combines high- and low-frequency vibrations to enhance cavitation effects, ideal for precision cleaning of complex-structured components (e.g., PCB boards, optical lenses).

- Immersible Vibrating Plate Design: Facilitates maintenance and extends equipment lifespan.

2. Eco-Friendly Design:

- Recirculating Filtration System: Extends cleaning fluid service life.

- Stainless Steel Construction (e.g., SUS304): Corrosion-resistant and easy to clean.

III. Application Scenarios

1. Optics Industry:

- Removal of oil stains, dust, fingerprints, and chemical residues from optical components.

2. Electronics Manufacturing:

- PCB Cleaning: Eliminates soldering residues, flux, and dust to ensure circuit board reliability.

- Precision parts: such as aviation parts, optical lenses before coating.

3. Medical and Research Fields:

- The disinfection and decontamination of surgical instruments and laboratory utensils shall comply with GMP standards.

4. Industrial Sector:

- Oil removal for automotive parts and metal molds to enhance surface treatment quality.

Product advantages

1、advanced equipment technology, exquisite workmanship

2、the normal service life of more than 15 years, the qualified rate of more than 95%, to reach the technical level of imported equipment, more cost-effective.

3、High cleanliness of equipment, special welding process for pipeline.

4、the manipulator can complete high-speed and accurate operation, replacing the uncertainty and inefficiency of manual operation, and realizing multiple tasks such as processing, assembly, handling and sorting.

5、our company has nearly 20 years of experience in technical and after-sales service team, from design and production to after-sales service to provide customers with professional solutions.

IV. Selection Guidelines

1. Based on Cleaning Requirements:

- High-Precision Cleaning (e.g., optical lenses): Prioritize dual-frequency ultrasonic + IPA vapor-phase cleaning systems.

- Bulk Industrial Cleaning (e.g., metal parts): Opt for multi-tank linked or fully automated spray systems.

2. Safety and Environmental Considerations:

- Explosion-proof design and solvent recovery systems are mandatory for chemical environments.

- Prioritize stainless steel equipment to prevent corrosion and secondary pollution.

3. Expandable Functions:

- Integrated temperature control and drying modules reduce process transition time.

V. Maintenance and Precautions

1. Routine Maintenance:

- Regularly replace filters and clean tank residues to ensure ultrasonic transducer efficiency.

- Monitor solvent concentration to prevent reduced cleaning efficacy due to volatilization.

2. Safe Operation:

- Avoid using alcohol-based equipment in enclosed spaces to mitigate explosion risks.

- Equip with automatic fire suppression systems to address emergencies.

For more models of products, please contact us. We will be happy to serve you!

在线留言